Professional Truck Driveline Repair Services in South Florida

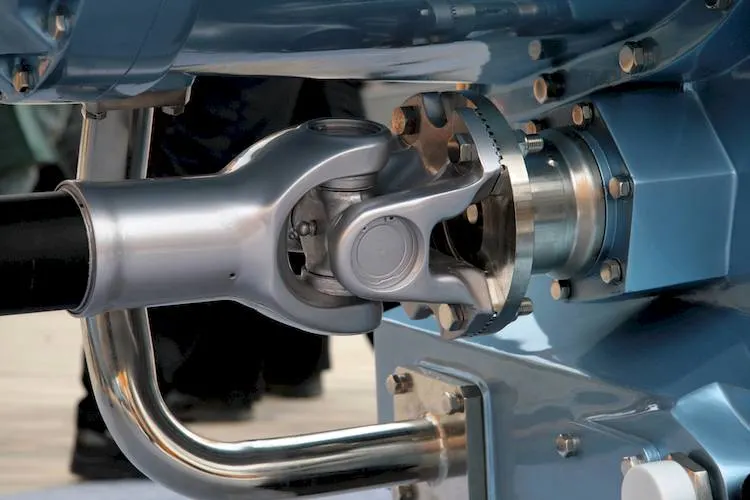

The driveline is your truck's power delivery backbone - a precision system including the driveshaft, U-joints, center bearings, axles, and differential that transfers torque from engine to wheels. Every component must work in perfect sync to handle the stress of hauling heavy commercial loads up to 80,000 pounds.

When driveline components fail, you'll experience power loss, poor fuel economy, dangerous vibrations, and potentially catastrophic failure leaving your truck stranded. Common issues our driveline repair shops diagnose include worn U-joints creating clunking sounds, unbalanced driveshafts causing highway vibrations, differential wear reducing torque delivery, and damaged axle shafts compromising power. These problems increase operating costs through wasted fuel and accelerated wear on transmission and related components.

At Southeast Truck Specialist Inc., our comprehensive truck driveline repair services keep your fleet operating at peak efficiency. Our ASE-certified technicians specialize in all driveline repair near me requests, from subtle vibrations indicating early U-joint wear to complete driveshaft replacement and differential rebuilds. We're experts in driveline repair and installation for all commercial truck applications.

Our Pompano Beach facility uses advanced diagnostic equipment - vibration analyzers, precision balancing machines, and computerized alignment tools - to accurately diagnose driveline problems. We stock quality U-joints, bearings, seals, and driveshaft components for fast repairs with minimal downtime.

We service all major truck brands: Freightliner, Peterbilt, Kenworth, Mack, International, Volvo, and Western Star. Our driveline repair services handle Class 6, 7, and 8 commercial trucks with configurations from single rear axle to tandem and tri-drive setups. Using OEM-quality parts and manufacturer torque specs, every driveline repair restores proper power transfer.

Our driveline repair shops near me serve fleet operators, owner-operators, and trucking companies throughout Miami-Dade, Broward, and Palm Beach counties with competitive pricing, flexible scheduling, and mobile driveline repair for emergencies.

Why Professional Driveline Maintenance is Key to Fleet Performance

Proper driveline maintenance is essential for operational efficiency and preventing costly downtime that can sideline your trucks and disrupt your business operations. Understanding the benefits of professional driveline repair services helps you make informed maintenance decisions that protect your investment:

- Maximum Power Transfer and Performance: A well-maintained driveline ensures maximum power transfer from the engine to the wheels with minimal loss through friction or mechanical inefficiency. This improves fuel economy by 3-8% compared to worn driveline components, enhances acceleration and hill-climbing ability, and restores the full torque delivery your truck was designed to provide. When driveline components wear, they create drag that forces the engine to work harder, wasting fuel and reducing available power for hauling loads.

- Elimination of Damaging Vibrations: Professional driveline repair services prevent the vibrations that can lead to driver fatigue, reduced steering control, and progressive damage to other vehicle components including the transmission, transfer case, cab mounts, and frame. Driveline vibrations at highway speeds create uncomfortable working conditions for drivers and accelerate wear throughout the entire vehicle. Our precision balancing and proper component alignment eliminate these destructive forces.

- Prevention of Catastrophic Failure: Investing in proactive driveline maintenance protects your assets from catastrophic failure that can cause sudden breakdowns, create dangerous road conditions, and result in expensive emergency repairs plus towing costs. A failed U-joint can destroy the driveshaft, damage the transmission output shaft, puncture brake lines or fuel tanks, and even cause loss of vehicle control. Regular inspection and timely component replacement prevent these severe failure modes.

- Extended Component Lifespan: Proper driveline maintenance extends the service life of expensive components like differentials, transmissions, and axle assemblies by ensuring they operate within design parameters without excessive stress, heat, or vibration. A $300 U-joint replacement today can prevent a $5,000 transmission repair tomorrow. Our preventative approach to driveline repair services maximizes your return on maintenance investment.

- Enhanced Safety and Reliability: A properly functioning driveline ensures your trucks remain reliable and productive on the road, reducing the risk of breakdowns in dangerous locations or adverse weather conditions. Drivers can operate with confidence knowing their vehicle will deliver consistent performance. This reliability translates to on-time deliveries, satisfied customers, and a positive reputation for your business.

Our Complete Driveline Repair and Installation Services in Pompano Beach

Our driveline repair shops in Pompano Beach are fully equipped to handle every aspect of your truck's driveline system, from initial diagnosis through final testing and road verification. Our comprehensive services include:

Driveshaft Repair and Balancing

We inspect, repair, and precision-balance driveshafts to eliminate vibrations that can cause damage to your transmission, transfer case, differential, and other connected components. Our service includes checking driveshaft runout with dial indicators, inspecting slip yokes for wear, examining center bearings for smooth operation, verifying proper yoke phasing, and dynamic balancing using professional equipment that ensures smooth operation at all speeds. We repair bent driveshafts when possible through straightening and re-balancing, replace damaged sections, and install new center bearings and slip yoke assemblies as needed. All driveshafts are balanced to within industry-standard tolerances to eliminate highway speed vibrations.

Universal Joint (U-Joint) Replacement

Worn or failing U-joints are one of the most common sources of clunking noises, driveline failure, and power delivery problems in commercial trucks. We provide expert U-joint replacement using heavy-duty, greaseable joints designed for commercial truck applications. Our service includes removing worn U-joints using hydraulic presses, inspecting yoke ears for wear or damage, installing premium replacement U-joints with proper snap ring or strap retention, and greasing all joints to manufacturer specifications. We stock U-joints for all common driveline configurations including single, double, and CV-style joints. Proper U-joint maintenance is critical - these small components handle enormous torque loads and their failure can cause immediate driveline destruction.

Differential Repair and Service

We service and repair differentials of all types, including standard open differentials, limited-slip differentials, locking differentials, and power divider units in tandem axle configurations. Our differential services include complete fluid changes using the correct viscosity and type (conventional or synthetic gear oil), inspection and replacement of ring and pinion gears for wear patterns or tooth damage, bearing replacement (carrier bearings, pinion bearings, and side bearings), seal replacement to prevent leaks, backlash adjustment to eliminate noise and ensure proper gear mesh, and complete differential rebuilds when necessary. We diagnose differential problems such as howling noises, whining sounds, clunking during direction changes, and vibrations during turns. Proper differential maintenance ensures optimal torque distribution to the wheels and prevents expensive internal failures.

Axle Shaft Repair and Replacement

We inspect axle shafts for wear, damage, bending, spline wear, and bearing surface condition, providing professional repair or replacement to maintain the integrity of your driveline. Our axle shaft services include removing and replacing damaged shafts, inspecting axle bearings and seals, checking wheel hub assemblies, verifying proper axle shaft end play, and installing new components with correct torque specifications. We handle both full-floating and semi-floating axle designs common in commercial trucks. Bent or damaged axle shafts create dangerous wheel wobble and can lead to sudden wheel separation if not addressed promptly.

Transmission and Transfer Case Service

We offer comprehensive services for related driveline components to ensure the entire power delivery system works in perfect harmony. Our transmission services include fluid and filter changes, external leak repairs, output shaft seal replacement, and basic diagnostic services for shifting problems or unusual noises. For transfer cases found in all-wheel drive and 4x4 trucks, we provide fluid changes, shift mechanism repairs, output seal replacement, and diagnosis of power delivery issues between axles. Proper maintenance of these components ensures reliable power input to the driveline system.

Center Bearing Replacement

The center bearing (also called a carrier bearing or hanger bearing) supports the driveshaft on longer trucks with two-piece driveshafts. We inspect center bearings for wear, noise, and rubber mount deterioration, replacing failed units with quality components properly aligned to eliminate vibration and reduce stress on U-joints.

Pinion Seal Replacement

Leaking pinion seals allow differential fluid to escape, potentially causing internal damage from lubrication loss. We replace pinion seals while maintaining proper pinion bearing preload and backlash settings to prevent differential damage.

Is It Time for a Driveline Inspection Warning Signs You Shouldn't Ignore

Your truck's driveline will often give clear warning signs before a major failure occurs. Recognizing these symptoms early and scheduling prompt truck driveline repair can prevent catastrophic breakdowns and save thousands in repair costs. If you or your drivers experience any of the following, it's time for a professional driveline inspection:

- Unusual Vibrations: One of the most common signs of driveline problems is vibration that intensifies with speed, particularly noticeable at highway speeds between 50-70 mph. This vibration can be felt throughout the vehicle - in the seat, steering wheel, floor, and shift lever. It may be constant or occur only at certain speeds. Causes include unbalanced driveshafts, worn U-joints with excessive play, damaged center bearings, incorrect driveline angles, or bent driveshafts from impact damage. These vibrations create uncomfortable driving conditions and cause progressive damage to transmission mounts, cab mounts, and other components if not addressed.

- Loud Clunking Noises: A distinct "clunk" sound when shifting from park to drive or reverse, or when changing between forward and reverse gears, often indicates a worn U-joint with excessive rotational play. This noise results from the loose joint taking up slack as torque direction changes. You may also hear clunking during hard acceleration or deceleration. Worn U-joints will eventually fail completely, potentially destroying the driveshaft and causing loss of power or even loss of vehicle control. This symptom requires immediate professional attention.

- Squeaking or Grinding Sounds: Persistent squeaking noises at low speeds, especially during initial movement or light acceleration, typically point to a dry or failing U-joint that lacks proper lubrication or has worn needle bearings inside. Grinding sounds, particularly during turns or under load, can indicate differential problems such as worn ring and pinion gears, damaged carrier bearings, or insufficient differential fluid. These sounds progressively worsen and indicate components operating outside their design parameters.

- Difficulty Turning or Noises While Turning: If you have trouble making turns, hear clicking, popping, or binding noises while cornering, or feel resistance in the steering, it could indicate problems with the axle shafts, CV joints (in front-wheel drive applications), or differential spider gears. Limited-slip differentials may chatter during turns if they lack proper lubrication or use incorrect fluid types. These symptoms affect vehicle maneuverability and can lead to component failure.

- Shuddering Upon Acceleration: A noticeable shudder, vibration, or jerking sensation when accelerating from a stop or during hard acceleration can signal several driveline issues including loose U-joints with rotational play, a failing center bearing that allows excessive driveshaft movement, worn transmission or differential mounts, or excessive backlash in the differential gears. This condition indicates components are not properly transferring torque and require immediate inspection.

- Loss of Power or Poor Acceleration: If your truck seems to lack power, accelerates poorly despite normal engine performance, or struggles on grades it previously handled easily, worn driveline components may be absorbing power rather than efficiently transferring it to the wheels.

- Burning Smell: A burning odor from under the truck, particularly from the differential area, can indicate overheating due to low fluid levels, excessive friction from worn components, or a failing bearing. This requires immediate attention to prevent complete failure.

Don't ignore these warning signs or attempt to "drive through" driveline problems. What starts as a $200 U-joint replacement can quickly escalate to a $5,000+ emergency repair involving driveshaft, transmission, and differential damage. Schedule a professional driveline inspection at the first sign of trouble. Our experienced technicians will diagnose the problem accurately, provide a detailed estimate, and perform repairs that restore your truck to proper operation.

Why Choose Our Driveline Repair Near Me

Advanced Facilities

Our facilities have cutting edge technology and tools to deliver top-tier service and quality work on all your trucks. With the latest diagnosis equipment, we can accurately identify and resolve issues with any size truck.

Experienced Technicians

Our team has over 20 years of experience in the heavy-duty truck repair industry. We bring expertise and dedication to every job, delivering outstanding customer service and ensuring your trucks run smoothly and safely.

Tailored Solutions for You

We pride ourselves on understanding that every truck and fleet is unique, which is why we offer customized maintenance and repairs to meet your specific needs. Whether you have a small fleet or many heavy-duty vehicles, we have the expertise to ensure they continue like new.

Commitment to Quality and Customer Satisfaction

At Southeast Truck Specialist, we are committed to providing exceptional service and customer satisfaction. We take great pride in our work and consistently strive to exceed expectations with every service we offer.

Frequently Asked Questions

Where can I find a truck brake repair near me in South Florida?

If you're searching for "truck driveline repair near me" or "driveline repair near me," our state-of-the-art driveline repair shop is conveniently located in Pompano Beach, Florida, at 1291 SW 27th Avenue Pompano Beach, FL 33069. SSoutheast Truck Specialist Inc. is one of the premier driveline repair shops for commercial truck operators throughout Miami-Dade, Broward, and Palm Beach counties. We serve fleet managers, owner-operators, and trucking companies from Fort Lauderdale, Miami, West Palm Beach, Boca Raton, Deerfield Beach, Delray Beach, Coral Springs, Hollywood, and surrounding South Florida communities.

What are the main components of a truck driveline system?

A truck's driveline system consists of several critical components that work together to transfer power from the engine to the wheels. The main components include the transmission (which receives power from the engine and provides gear ratios), the driveshaft (a rotating shaft that carries torque from the transmission to the differential), universal joints or U-joints (flexible couplings that allow the driveshaft to operate at angles as the suspension moves), center bearings (support bearings on two-piece driveshafts), slip yokes (allow driveshaft length changes during suspension travel), the differential (splits torque between drive wheels and allows them to rotate at different speeds during turns), and axle shafts (transfer power from the differential to individual wheels). In 4x4 or all-wheel drive trucks, a transfer case is also part of the system, distributing power between front and rear axles. Our comprehensive driveline repair and installation services cover all these critical parts, ensuring your entire power delivery system functions optimally.

What does a U-joint do and why do they fail?

A universal joint (U-joint) is a flexible coupling component that allows the driveshaft to transmit power at varying angles as the vehicle's suspension compresses and extends during normal driving. U-joints accommodate the constant angle changes between the transmission output and the differential input while maintaining smooth power transfer. They consist of a cross-shaped spider with needle bearings in four bearing caps. U-joints fail for several reasons: lack of proper lubrication causing bearing wear, normal wear from millions of rotation cycles, corrosion from water intrusion through damaged seals, impact damage from debris or rough roads, operating at incorrect angles creating excessive stress, and overloading beyond their design capacity. A failing U-joint is one of the most common reasons for truck driveline repair. Symptoms include clunking when changing gears, squeaking during acceleration, vibrations at highway speeds, and visible play when you attempt to rotate the driveshaft by hand. Failed U-joints can cause immediate driveline destruction and should be replaced at the first sign of wear.

Can a bad driveline affect fuel economy?

Yes, absolutely. A driveline with worn components creates extra drag, friction, and vibration, forcing the engine to work harder and consume more fuel to maintain speed and performance. Specific driveline problems that reduce fuel efficiency include worn U-joints with excessive friction and binding, unbalanced driveshafts requiring extra energy to rotate, low differential fluid levels increasing internal friction, worn differential bearings creating drag, incorrect driveline angles causing power loss, and dragging brake components related to axle problems. Depending on the severity of driveline wear, fuel economy can decrease by 3-8% or more. Our professional driveline repair services can help restore your truck's efficiency by eliminating these sources of power loss and parasitic drag. When we repair driveline components, we're not just fixing problems - we're restoring your truck to its designed fuel efficiency. Many fleet operators notice measurable fuel economy improvements after addressing driveline issues, which quickly offsets the cost of repairs through reduced fuel expenses.

How often should truck driveline components be inspected?

Driveline components should be inspected regularly as part of your preventative maintenance program. We recommend professional driveline inspections every 25,000-50,000 miles depending on operating conditions, or at least once annually during comprehensive vehicle inspections. Trucks operating in severe-duty applications - such as off-road use, frequent stop-and-go driving, heavy hauling, or mountainous terrain - should have more frequent driveline inspections, potentially every 15,000-25,000 miles. Key inspection points include checking U-joints for play, wear, and proper lubrication; inspecting driveshafts for damage, runout, and balance; examining center bearings for noise and wear; checking differential fluid level and condition; inspecting for fluid leaks from seals; and verifying proper driveline angles. Additionally, drivers should perform visual checks during pre-trip inspections looking for obvious damage, leaks, or loose components. Early detection of driveline problems through regular inspections prevents catastrophic failures and saves significant money compared to emergency repairs.

What causes driveline vibration and how is it fixed?

Driveline vibration can stem from multiple sources and requires systematic diagnosis to identify the root cause. Common causes include unbalanced driveshafts (from damaged balance weights, bent shafts, or accumulated debris), worn U-joints with excessive play allowing the driveshaft to oscillate, failed or worn center bearings allowing unwanted movement, incorrect driveline operating angles (from modified ride height, worn suspension, or improper installation), bent or damaged driveshafts from impact or stress, loose or damaged mounting points, and out-of-balance wheels or tires (sometimes mistaken for driveline problems). To fix driveline vibration, our technicians first identify the source through test drives, visual inspection, and measurement. Solutions may include driveshaft balancing using precision equipment, U-joint replacement, center bearing replacement, driveline angle correction through shims or ride height adjustment, driveshaft straightening or replacement, and securing loose mounting hardware. We take a comprehensive approach to vibration diagnosis rather than guessing, which ensures we fix the actual problem and don't waste your money on unnecessary parts.

How long does driveline repair take?

Repair time varies based on the specific work needed and parts availability. Simple U-joint replacement can often be completed in 3-5 hours for a single driveshaft. Driveshaft removal, balancing, and reinstallation typically takes 4-6 hours. Center bearing replacement takes 2-4 hours. More extensive repairs like differential rebuilds or axle shaft replacement may require 1-3 days depending on parts availability and the extent of work. Custom driveshaft fabrication or modification can take 2-5 days. We understand that downtime costs your business money, so we work efficiently while maintaining our high standards for quality. For fleet customers, we offer expedited service, after-hours work, and can sometimes provide loaner driveshafts to minimize your truck's time off the road. We'll provide an accurate time estimate when we diagnose your specific driveline problem and will keep you updated throughout the repair process.

Do you service all truck makes and driveline configurations?

Yes, our experienced technicians service all major commercial truck brands including Freightliner, Peterbilt, Kenworth, Mack, International, Volvo, Western Star, Isuzu, and Hino. We work on Class 6, 7, and 8 trucks with various driveline configurations including single rear axle, tandem rear axle (with power dividers), tri-drive setups, 4x4 and all-wheel drive systems, and specialty configurations. We're equipped to handle both standard driveshafts and specialized heavy-duty drivelines. Whether you operate highway tractors, straight trucks, dump trucks, delivery vehicles, or specialty commercial equipment, we have the knowledge, tools, and parts access to service your driveline properly.

What's the difference between a driveshaft and a drive axle?

Though the terms sound similar, they're different components. The driveshaft is the rotating tube or shaft that transfers torque from the transmission to the differential. It may be one piece or two pieces connected by a center bearing, and it includes U-joints at each end to accommodate angle changes. The drive axle (or drive axles) refers to the axle assembly that receives power from the differential and includes the axle housing, differential assembly, axle shafts, wheel hubs, and related components. The driveshaft connects the transmission to the drive axle. In a typical rear-wheel drive truck, power flows from the transmission through the driveshaft to the differential in the drive axle, then through the axle shafts to the wheels. Both are critical parts of the complete driveline system, and we service both as part of our comprehensive truck driveline repair services.

Do you offer mobile driveline repair services?

Yes, we offer mobile driveline repair services for certain repairs that can be safely performed at your location. This service is particularly useful for U-joint replacements, driveline inspections, minor adjustments, fluid services, and situations where the truck cannot be safely driven to our shop due to driveline damage. Our mobile service vehicles carry specialized driveline tools, common replacement parts, and diagnostic equipment. Mobile service is ideal for fleet yards, distribution centers, job sites, or roadside breakdowns. However, some driveline repairs requiring driveshaft balancing, major differential work, or specialized equipment must be performed at our fully-equipped facility. Contact us to discuss whether mobile driveline repair is appropriate for your specific situation and to schedule a mobile service appointment. We'll dispatch a technician to your location and provide the same high-quality service you'd receive at our Pompano Beach shop.

How can I get in touch?

You can reach us by calling our Pompano Beach shop at 954-970-3651 to speak with one of our diesel specialists, or feel free to visit us in person to discuss your vehicle's needs.

Schedule Your Driveline Repair Truck Today

Don't wait until breakdowns happen - invest in reliable truck preventive maintenance with Southeast Truck Specialist. Give us a call at 954-970-3651 to schedule an inspection and keep your fleet running smoothly, safely, and efficiently across Florida's roads.